Sisitemu

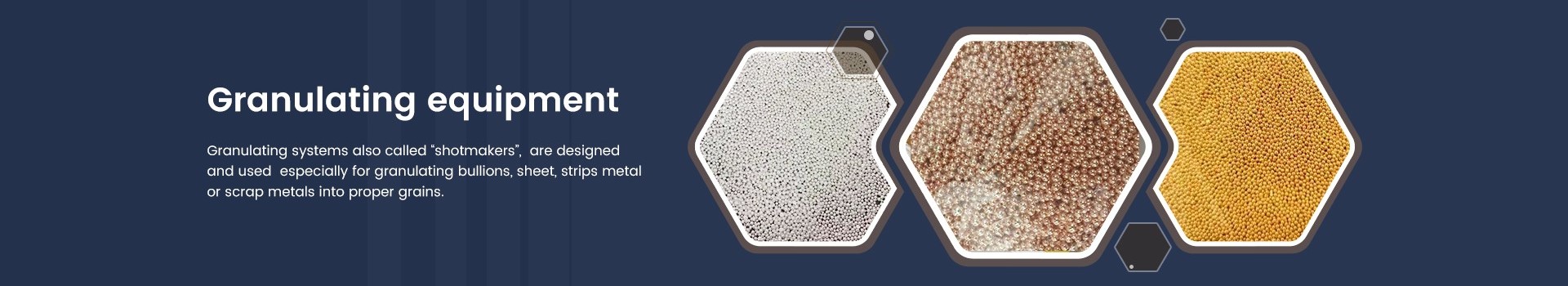

Sisitemu yo gusya nayo yitwa "abakora amasasu", yarateguwe kandi ikoreshwa cyane cyane mugusya ibimasa, urupapuro, gukuramo ibyuma cyangwa ibisigazwa byimbuto mubinyampeke bikwiye. Ibigega bya granulation biroroshye cyane kubikuramo kugirango bisukure. Kuramo ikiganza kugirango ukureho byoroshye kwinjiza tank. Ibikoresho bidahitamo imashini itwara vacuum cyangwa imashini ikomeza hamwe na tanki ya granuline ni igisubizo cyo gusya rimwe na rimwe. Ibigega bya granulation birahari kumashini zose murukurikirane rwa VPC. Sisitemu isanzwe yo gusya ifite ibikoresho bifite ibiziga bine bigenda byoroshye kandi bisohoka.

-

Imashini ya Granulator Imashini ya Zahabu Ifeza Umuringa 4kg 6kg 8kg10kg15kg

1. Hamwe no kugenzura ubushyuhe, ubunyangamugayo bugera kuri ± 1 ° C.

2. Igishushanyo mbonera-muntu, imikorere iroroshye kurenza abandi.

3. Koresha umugenzuzi wa Mitsubishi yatumijwe hanze.

4. Ifeza ya Granulator hamwe no kugenzura ubushyuhe (Imashini ya Zahabu Ifata Imashini, Imashini ya Granile).

5. Iyi mashini ikoresha tekinoroji yo gushyushya IGBT, ingaruka zo gutera ni nziza cyane, sisitemu ihamye kandi itekanye, ubushobozi bwa zahabu yashongeshejwe ntabwo ari ubushake, kandi ibyuma bisya byerekana neza.

6. Umuvuduko wa granulation urihuta kandi nta rusaku. Imikorere yuzuye yo kugerageza no kurinda ituma imashini yose itekana kandi iramba.

7. Imashini ifite igishushanyo mbonera kandi umubiri ufite umwanya wubusa.

-

Imashini ya platine yamashanyarazi Imashini 10kg

Imashini ya Hasung Platinum Shot Maker Granulating Machine ugereranije nibicuruzwa bisa kumasoko, ifite ibyiza ntagereranywa mubijyanye nimikorere, ubuziranenge, isura, nibindi, kandi ifite izina ryiza kumasoko.Hasung avuga muri make inenge yibicuruzwa byashize, kandi bikomeza kubateza imbere. Ibisobanuro bya Hasung Platinum Shot Maker Granulating Machine irashobora gutegurwa ukurikije ibyo ukeneye.

Ibyiza byingenzi byibisekuru bishya byo kurasa

Kwishyiriraho byoroshye tank ya granulation hamwe na platform

Imikorere yo mu rwego rwo hejuru

Ergonomique kandi iringaniye neza igishushanyo mbonera cyoroshye kandi cyoroshye

Imyitwarire myiza yimyitwarire yamazi akonje

Gutandukanya kwizewe kwamazi na granules -

Vacuum Shot Maker ya Zahabu Ifeza Umuringa 4kg 8kg 10kg

Igishushanyo cyiyi sisitemu ya vacuum granulator ishingiye kubikenewe nyabyo byicyuma cyagaciro ukoresheje tekinoroji igezweho yo gushyushya induction.

Imashini ya vacuum ikoreshwa mu gukora ibinyampeke byujuje ubuziranenge kandi bihuje ibinyabuzima by’amabuye y'agaciro nka zahabu, ifeza, umuringa, hamwe na alloys, guhera ku bikoresho fatizo byashongeshejwe na Hasung induction bishyushya mu kirere kirinda gaze, hanyuma bikamanikwa mu kigega cy'amazi kirengana. unyuze mubice byinshi bifunguye bikora nkibimena.

Imashini ya vacuum ifata vacuum yuzuye hamwe na inert ya gaz gushonga no kuyisya, imashini irashobora guhita ishonga mugushonga, gukurura electromagnetic, no gukonjesha mucyumba gifunze + vacuum / inert yo gukingira gaze, kugirango ibicuruzwa bigire ibiranga nta okiside, super igihombo gito, nta pore, nta gutandukanya ibara, nuburanga bwiza hamwe nubunini bumwe.

Ibi bikoresho bikoresha sisitemu yo kugenzura porogaramu ya Mitsubishi PLC, SMC pneumatic na Panasonic servo moteri hamwe nibindi bikoresho bizwi cyane murugo ndetse no mumahanga.

-

Sisitemu yo hejuru ya Vacuum Sisitemu ya Zahabu Ifeza Umuringa 20kg 50kg 100kg

Imashini nini ya vacuum isunika ibyuma by'agaciro kugirango baterwe insinga: zahabu, ifeza n'umuringa, insinga ihuza ikoreshwa cyane cyane mu bikoresho bya semiconductor, ibikoresho byo gusudira bifotora, ibikoresho by'ubuvuzi, imashini zikoresha ubwenge. , urupapuro, cyangwa ibisakuzo mubinyampeke bikwiye. Ibigega bya granulation biroroshye cyane kubikuramo kugirango bisukure. Imashini za HS-VGR Imashini nini ya Vacuum iraboneka ifite ubushobozi bukomeye kuva 20kg kugeza 100kg. Ibikoresho byumubiri bifashisha ibyuma 304 bidafite ingese byemeza ubuziranenge ubuzima bwawe bwose ukoresheje, hamwe nubushakashatsi bwakozwe kugirango buzuze ubuziranenge busabwa.

Ibyifuzo byingenzi:

1. Gutegura ibishishwa bivuye muri zahabu na master alloy

2. Gutegura ibice bivanze

3. Gutegura ibinyomoro biva mubice

4. Gusukura ibyuma bimaze guterwa

5. Gukora ibinyampeke byibyuma byagaciroUrukurikirane rwa VGR rwakozwe mugukora granules yicyuma gifite ingano ingana na mm 1.5 na 4mm. Sisitemu ishingiye ku bice bya Hasung granulation, ariko ibice byose byingenzi, cyane cyane sisitemu yindege, ni iterambere ryihariye.

Ubushobozi bunini nka 100kg vacuum granulation sisitemu birashoboka guhitamo ibikoresho bya sisitemu yo kugenzura Mitsubishi PLC Touch Panel.

Ibikoresho bidahwitse byumuvuduko wa vacuum cyangwa imashini ikomeza guterana hamwe na tank ya granulation nigisubizo kiboneye cyo guhunika rimwe na rimwe. Ibigega bya granulation birahari kumashini zose murukurikirane rwa VC.

Ibyiza byingenzi byibisekuru bishya byabashinzwe kurasa:

1. Kwishyiriraho byoroshye ikigega cya granulation

2. Guhindura byihuse hagati yo gukina no gusya

3. Igishushanyo mbonera kandi cyuzuye kiringaniye kuburyo bworoshye kandi bworoshye

4. Gukoresha neza uburyo bwo gutembera bwamazi akonje

5. Gutandukanya kwizewe kwamazi na granules

6. Imbaraga zikomeye kandi zikora neza kubutare bwagaciro butunganya amatsinda.

7. Kuzigama ingufu, gushonga vuba. -

Imashini isya ibyuma bya zahabu kumuringa wa zahabu Umuringa 20kg 30kg 50kg 100kg 150kg

1. Hamwe no kugenzura ubushyuhe, ubunyangamugayo bugera kuri ± 1 ° C.

2. Igishushanyo mbonera-muntu, imikorere iroroshye kurenza abandi.

3. Koresha umugenzuzi wa Mitsubishi yatumijwe hanze.

4. Ifeza ya Granulator hamwe no kugenzura ubushyuhe (Imashini ya Zahabu Ifata Imashini, Imashini ya Granile).

5. Iyi mashini ikoresha tekinoroji yo gushyushya IGBT, ingaruka zo gutera ni nziza cyane, sisitemu ihamye kandi itekanye, ubushobozi bwa zahabu yashongeshejwe ntabwo ari ubushake, kandi ibyuma bisya byerekana neza.

6. Umuvuduko wa granulation urihuta kandi nta rusaku. Imikorere yuzuye yo kugerageza no kurinda ituma imashini yose itekana kandi iramba.

7. Imashini ifite igishushanyo mbonera kandi umubiri ufite umwanya wubusa.

-

Ingano yoroheje Metal Granulator Ibikoresho byo Kuringaniza Zahabu

Ingano ntoya. Hamwe no kugenzura ubushyuhe, ubunyangamugayo bugera kuri ± 1 ° C.

Igishushanyo mbonera-muntu, imikorere iroroshye kurenza abandi.

Koresha Mitsubishi mugenzuzi.Iyi mashini ikoresha Ubudage IGBT ikorana buhanga ryo gushyushya, ingaruka zo gutera ni nziza cyane, sisitemu ihamye kandi ifite umutekano, ubushobozi bwa zahabu yashongeshejwe ntibigomba, kandi ibyuma bisya byerekana neza. Umuvuduko wa granulation urihuta kandi nta rusaku. Imikorere yuzuye yo kugerageza no kurinda ituma imashini yose itekana kandi iramba. Imashini ifite igishushanyo mbonera kandi umubiri ufite umwanya wubusa.

Gukoresha udafite compressor de air, guterwa nintoki zifungura imashini zihagarara.

Sisitemu ya GS Series granulation sisitemu ikwiranye nubushobozi buke kuva 1kg kugeza 8kg ubushobozi (zahabu), nibyiza kubakiriya bafite umwanya muto.

Gusya ibyuma ni iki?

Granulation (kuva mu kilatini: granum = “ingano”) ni tekinike yumucuzi wa zahabu aho ubuso bwumutako bushushanyijeho uduce duto twibyuma byagaciro, byitwa granules, ukurikije igishushanyo mbonera. Ubushakashatsi bwa kera mu bucukumbuzi bw'amabuye y'agaciro bwakozwe muri ubwo buhanga bwabonetse mu mva z'umwami za Ur, muri Mezopotamiya no mu mwaka wa 2500 mbere ya Yesu. Kuva muri kariya gace, ubwo buryo bwakwirakwiriye muri Anatoliya, muri Siriya, muri Troy (2100 mbere ya Yesu) hanyuma amaherezo bugera muri Etruriya (Ikinyejana cya 8 mbere ya Yesu). Buhoro buhoro umuco wa Etruscan wabuze buhoro buhoro hagati yikinyejana cya gatatu n'icya kabiri mbere ya Yesu mbere yaryo wagize uruhare mu kugabanuka kwa granulation.1 Abagereki ba kera bakoreshaga imirimo yo guhunika, ariko abanyabukorikori ba Etruria ni bo bamenyekanye cyane kubera ubwo buhanga kubera uburyo bwabo butangaje bwo gukoresha ifu nziza ya granulation2 idakoreshwa bigaragara kugurisha cyane.

Granulation birashoboka ko ari amayobera kandi ashimishije muburyo bwa kera bwo gushushanya. Yinjijwe n’abanyabukorikori Fenici na Greci muri Etruria mu kinyejana cya 8 mbere ya Yesu, aho ubumenyi bwa metallurgie no gukoresha amabuye y'agaciro bwari bumaze kugera ku rwego rwo hejuru, abanyabukorikori ba zahabu bo muri Etruscan bakoze ubwo buhanga ubwabo kugira ngo bahimbe ibihangano by’ubukorikori butagereranywa n’ubwiza.

Mu gice cya mbere cy’imyaka ya 1800 ubucukuzi bwinshi bwakorewe hafi y’i Roma (Cerveteri, Toscanella na Vulci) no mu Burusiya bw’Amajyepfo (Kertch na Taman peninsulas) bwerekanaga imitako ya kera ya Etruscan n’Ubugereki. Iyi mitako yari itatswe na granulation. Imitako yaje kumenyeshwa umuryango wa Castellani wabanyabutare bagize uruhare runini mubushakashatsi bwimitako ya kera. Ibyavuye mu mva zashyinguwemo Etruscan byakuruye abantu benshi kubera gukoresha granules nziza cyane. Alessandro Castellani yize ibi bihangano muburyo burambuye kugirango agerageze guhishura uburyo bwabo bwo guhimba. Mu ntangiriro z'ikinyejana cya 20, nyuma y'urupfu rwa Castellani, ni bwo amaherezo igisubizo cyo kugurisha colloidal / eutectic.

Nubwo ibanga ryakomeje kuba amayobera kuri Castellanis no mu gihe cyabo, imitako ya Etruscan iherutse kuvumburwa yateje ubucukuzi bw'imitako ya kera mu myaka ya za 1850. Ubuhanga bwo gucura zahabu bwavumbuwe bufasha Castellani nabandi kubyara mu budahemuka bimwe mu mitako myiza ya kera yacukuwe. Benshi murubwo buhanga bwari butandukanye cyane nabakoreshwa na Etruscans nyamara baracyatanga ibisubizo byoroshye. Umubare wibi bintu byubucukuzi bwa Archaeological Revival ubu biri mubikusanyirizo byingenzi byimitako ku isi, hamwe na bagenzi babo ba kera.

GRANULES

Ibinyampeke bikozwe mu kivunge kimwe nicyuma bazakoreshwa. Uburyo bumwe butangirana no kuzunguza urupapuro ruto cyane rwicyuma no gukubita impande zifunganye cyane kuruhande. Impande zaciwe kandi ibisubizo ni byinshi bito cyangwa platine yicyuma. Ubundi buryo bwo gukora ibinyampeke bukoresha insinga zoroshye cyane zegeranye hafi ya mandel yoroheje, nkurushinge. Igiceri gicibwa mo impeta ntoya cyane. Ibi birema impeta zingana cyane bivamo ingano zingana. Intego nugukora ibice byinshi bingana bifite diameter itarenze mm 1.

Amashanyarazi cyangwa impeta zo gusimbuka zometseho ifu yamakara kugirango birinde gufatana mugihe cyo kurasa. Hasi yikintu gitwikiriye igipfundikizo cyamakara kandi ibyuma byanyanyagiye hejuru kuburyo bitandukanijwe neza bishoboka. Ibi bikurikirwa nigice gishya cyifu yamakara nibindi bice byicyuma kugeza igihe ingenzi zuzuye hafi bitatu bya kane byuzuye. Ikibumbano kirasa mu itanura cyangwa mu ziko, kandi ibyuma by'agaciro byinjira mu bice bito ku bushyuhe bwo gushonga kugirango bivangwe. Iyi sisitemu nshya yaremye isigaye ikonje. Nyuma, basukurwa mumazi cyangwa, niba hazakoreshwa tekinike yo kugurisha, ikarishye muri aside.

Granules zingana zingana ntabwo zabyara igishushanyo gishimishije. Kubera ko bidashoboka ko umucuzi wa zahabu akora ibice bihuye neza na diameter imwe, granules igomba gutondekwa mbere yo kuyikoresha. Urukurikirane rwibisumizi bikoreshwa mugutondekanya granules.

Nigute ushobora gukora ishoti rya zahabu?

Ese inzira yo gukora ishoti rya zahabu isuka gusa zahabu yashongeshejwe mumazi umaze kuyishyushya? Cyangwa byose ubikora icyarimwe? Whats intego yo gukora ishoti rya zahabu aho kuba ingots ect.

Isasu rya zahabu ntabwo ryakozwe mugusuka kumunwa wikintu. Igomba gusohoka binyuze mumutwe. Urashobora gukora ikintu cyoroshye ucukura umwobo muto (1/8 ") munsi yisahani yashonga, hanyuma igashyirwa hejuru yikintu cyawe cyamazi, hamwe nigitereko gikinira kumasahani, kizengurutse umwobo. Ibyo birinda. zahabu yo gukonjesha mu isahani iyo yimuwe mu isahani ishonga ifu ya zahabu yashongeshejwe Kubwimpamvu zahoraga zigoye kubyumva, zikora ibisasu, aho kuba ibigori.

Kurasa bikundwa nabakoresha zahabu, kuko bituma gupima umubare wifuzwa byoroshye. Abanyabukorikori b'abanyabwenge b'ubwenge ntibashonga zahabu nyinshi icyarimwe, bitabaye ibyo bishobora kuganisha ku guta inenge (gushiramo gaze).

Mugushonga gusa amafaranga akenewe, umubare muto usigaye (isoko) urashobora gushongeshwa nicyiciro gikurikiraho, ukemeza ko zahabu yongeye gushonga idateranya.

Ikibazo cyo gushonga zahabu inshuro nyinshi nuko ibyuma shingiro (mubisanzwe umuringa, ariko ntibigarukira kumuringa) okiside hanyuma igatangira gukora gaze yegeranya mumifuka mito mumashanyarazi. Benshi muri buri mutako ukora casting yagize uburambe, kandi akenshi abara impamvu batazabikora, cyangwa badahitamo gukoresha zahabu yakoreshejwe mbere.