Ibicuruzwa

-

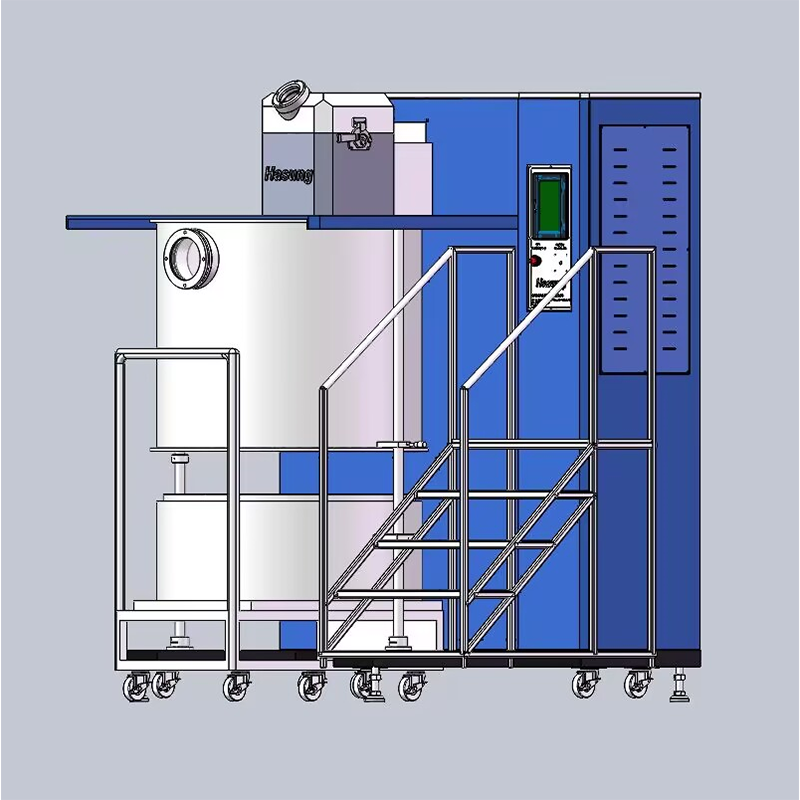

Imashini ikomeza kumashanyarazi ya zahabu ya zahabu Umuringa 20kg 30kg 50kg 100kg

1.Mu kanya nkifeza ya zahabu ya strip wire wire inkoniimashini ikomezakubera imitako yatangijwe ku isoko, yakiriye ibitekerezo byiza byabakiriya benshi, bavuze ko ubu bwoko bwibicuruzwa bushobora gukemura neza ibyo bakeneye.Ikindi kandi, ibicuruzwa bikoreshwa cyane muri Metal Casting.

2.Imashini ikomeza yo gukora imashini ikora Rod Strip hamwe na 20kg 30kg 50kg 100kg ugereranije nibicuruzwa bisa kumasoko, ifite ibyiza bitangaje ntagereranywa mubikorwa, ubuziranenge, isura, nibindi, kandi ifite izina ryiza kumasoko.Hasung incamake inenge yibicuruzwa byashize, kandi bikomeza kunoza. Ibisobanuro byimashini ikomeza yo gukora imashini ikora imigozi ya Rod Strip hamwe na 20kg 30kg 50kg 100kg irashobora gutegurwa ukurikije ibyo ukeneye.

-

Imashini zitunganya ibyuma bya zahabu Ibikoresho byo gukora ibikoresho byo gutunganya zahabu

Kumenyekanisha ibikoresho :

1. Emera kwinjiza inshuro ziciriritse, igihe gito cyo gushonga no gukora neza.

2. Icyumba cyo gushonga gikoresha gaze ya inert ikoreshwa mukurinda okiside yibikoresho byibyuma no kwinjiza umwanda. Kubwiyi ntego, irakwiriye ibikoresho byuma-byera cyane cyangwa gushonga birimo ibintu bya okiside byoroshye.

3. Ibikorwa byo gukanika imashini munsi ya vacuum byemewe, kandi ibara ntirishobora gutandukana.

4. Gushonga birinzwe na gaze ya inert ifite isuku nyinshi, bityo grafite ruthenium ifite igihombo gike cyane.

5. Ukoresheje Tayiwani Weinview / Siemens PLC mugenzuzi, imikorere iroroshye.

6. Ifumbire ihita ishyuha mugihe cyo gusuka kugirango hamenyekane ubuziranenge bwa casting.

7. Hamwe nibirango byinshi byamamaye kwisi bizwi kugirango ubuziranenge bwiza.8. Byinshi bikoreshwa mugutunganya zahabu.

-

Ifumbire ya Vacuum Induction yo gushonga (VIM) FIM / FPt (Platinum, Paldium Rhodium na Alloys)

FIM / FPt ni itanura rya vacuum ryo gushonga platine, palladium, rhodium, ibyuma, hamwe nubushyuhe bwo hejuru hamwe nuburyo bwo kugoreka.

Irashobora gukoreshwa kugirango ibone gushonga neza kwa platine na palladium ivanze nta gaze irimo.

Irashobora gushonga kuva byibuze 500g kugeza kuri 10kg ya platine muminota.

Igice cyo gushonga kigizwe n'amazi akonjeshejwe n'amazi adafite ibyuma aho ikariso izunguruka cyane hamwe na ingot yo gushiramo.

Icyiciro cyo gushonga, homogenisation hamwe na casting icyiciro gishobora kubera munsi yumwanya cyangwa mukirere gikingira.

Itanura ryuzuye hamwe na:

- Icyiciro cya kabiri kizunguruka vane vacuum pompe mu bwogero bwamavuta;

- Umuvuduko ukabije wibikoresho bya sensor;

- Pyrometero nziza yo kugenzura ubushyuhe;

- Byinshi byukuri bya digitale ya vacuum ihindura gusoma gusoma + Kwerekana.

Ibyiza

- Ikoranabuhanga ryo gushonga

- Sisitemu / Sisitemu yo kugorora

- Ubushyuhe bwo hejuru

Ikoranabuhanga rya HasungUbushyuhe bwo hejuru bwa Vacuum Induction Gushonga Itanura Ikigereranyo cya Vacuum Gushonga Itanura

Ibiranga ibicuruzwa

1. Umuvuduko ushonga vuba, ubushyuhe burashobora kugera hejuru ya 2200 ℃

2. Hamwe nimikorere yo gukanika imashini, ibikoresho bizunguruka cyane

3. Bifite ibikoresho byo kugenzura ubushyuhe bwa porogaramu, shiraho umurongo wo gushyushya cyangwa gukonjesha ukurikije ibisabwa, inzira izahita ishyuha cyangwa ikonje ukurikije iki gikorwa

4. Hamwe nigikoresho gisuka, icyitegererezo cyashongeshejwe gishobora gusukwa mububiko bwateguwe, kandi imiterere yicyitegererezo ushaka irashobora gusukwa.

5. Irashobora gushonga mubihe bitandukanye byikirere: gushonga mukirere, ikirere gikingira hamwe nikirere cyinshi, kugura ibikoresho bimwe, kumenya imirimo itandukanye; bika ikiguzi cyawe kurwego runaka.

6. Hamwe na sisitemu yo kugaburira ya kabiri: Irashobora kumenya kongeramo ibindi bintu mugihe cyo gushonga, bikworohera gutegura ingero zitandukanye.

7. Umubiri w'itanura ni ibyuma byose bidafite ingese hamwe no gukonjesha amazi kugirango umenye neza ko ubushyuhe bwikibabi buri munsi ya 35 ° C kugirango urinde umutekano wawe bwite.

-

Imashini yo gushonga ya Tilting Imashini ya Zahabu Ifeza 2kg 3kg 4kg 5kg 6kg

Igishushanyo mbonera cya sisitemu yo gushonga ishingiye kubikenewe byumushinga nibikorwa, ukoresheje tekinoroji igezweho. Umutekano wishingiwe.

.

2. Ukoresheje imikorere ya electromagnetic ikora, nta gutandukanya ibara.

3. Ifata sisitemu yo kugenzura amakosa (anti-umuswa) sisitemu yo kugenzura byikora, byoroshye gukoresha.

4. Ukoresheje sisitemu yo kugenzura ubushyuhe bwa PID, ubushyuhe burarenze (± 1 ° C) (bidashoboka).

5. Ibikoresho byo gushonga HS-TFQ byatejwe imbere byigenga kandi bikozwe hamwe nibikoresho bya tekinike bigezweho byo gushonga no guta zahabu, ifeza, umuringa, nibindi.

Urukurikirane rwa HS-TFQ rwagenewe gushonga platine, palladium, Rhodium, zahabu, ifeza, umuringa nandi mavuta.

6.Ibikoresho bikoresha ibicuruzwa byinshi byamamare byamahanga.

7. Ikomeza gushyuha mugihe usuka amavuta yicyuma muburyo bwiza butuma abayikoresha babona casting nziza.

-

Amashanyarazi ya Oven Induction Yihuta Gushonga 20kg 30kg 50kg 100kg Intoki Zigoramye Zahabu yo gushonga

Gushonga Amashyiga yo gushonga ibyuma byinshi mubyuma cyangwa ibimasa.

Izi mashini zagenewe gushonga byinshi, urugero muruganda rutunganya zahabu kugirango rushobore gushonga 50 kg cyangwa 100kg kuri buri cyiciro.

Hasung TF ikurikirana - yagerageje kandi igeragezwa mubishingwe no mumatsinda meza yo gutunganya ibyuma.Amatanura yacu yo gushonga akoreshwa cyane mubice bibiri:

1. Kugirango ushongeshe ibyuma byinshi nka zahabu, ifeza cyangwa inganda zikora inganda nko guta ibisigazwa, 15KW, 30KW, hamwe n’ibisohoka 60KW ntarengwa hamwe no guhuza imirongo mike bisobanura gushonga byihuse bishimira ibisubizo byiza biva mu Bushinwa - ndetse no ku bwinshi - kandi byiza cyane binyuze-kuvanga.

2. Gutera ibice binini, biremereye nyuma yo guterera mu zindi nganda.

Amatanura yoroheje kandi ahenze cyane yo gutanura kuva TF1 kugeza TF15 akoreshwa munganda zimitako no mububiko bwibyuma byagaciro, nibintu bishya rwose. Bafite ibikoresho bishya byerekana ingufu za induction bigera aho bishonga byihuse kandi byemeza kuvanga neza no guhuza ibinyabuzima byashongeshejwe. Moderi ya TF20 kugeza TF100, Ukurikije icyitegererezo, ubushobozi buva mubunini bwingana na 20kg kugeza 100kg kuri zahabu, cyane cyane kumasosiyete akora amabuye y'agaciro.

Amatanura ya TFQ ya tilting yagenewe kuri platine na zahabu, ibyuma byose nka platine, palladium, ibyuma bitagira umwanda, zahabu, ifeza, umuringa, ibishishwa nibindi, bishobora gushonga mumashini imwe muguhindura umusaraba gusa.

Ubu bwoko bw'itanura ni bwiza bwo gushonga kwa platine, bityo iyo usutse, imashini ikomeza gushyuha kugeza urangije gusuka, hanyuma usuke uhagarike mu buryo bwikora iyo birangiye.

-

Induction Gushonga Itanura rya Zahabu Platinum Ifeza Umuringa Rhodium Palladium

Sisitemu yo gushonga ya MU ishingiye kubikenewe nyabyo byo gushonga imitako hamwe nibyuma byagaciro byo gutunganya intego.

1. HS-MU ibice byo gushonga byatejwe imbere byigenga kandi bikozwe hamwe nibikoresho bya tekiniki bigezweho byo gushonga no guta zahabu, ifeza, umuringa nibindi bivangwa.

2. Itanura rya HS-MUQ rifite ibyuma bitanga amashanyarazi imwe ariko bikoreshwa muburyo bwo gushonga no guta platine, palladium, ibyuma bitagira umwanda, zahabu, ifeza, umuringa nandi mavuta, bishobora gukoreshwa muguhindura umusaraba gusa. Biroroshye kandi byoroshye.

-

1kg 2kg Mini Induction Gushonga Itanura rya Zahabu Ifeza

Ibiro bya mini induction yo gushonga itanura, ubushobozi kuva 1kg-2kg, bifata iminota 1-2 yo gushonga icyiciro kimwe cyicyuma. Iza muburyo bworoshye kandi irashobora kuba amasaha 24 idahwema gukora. Na none, itanura ryicyuma ryangiza ibidukikije cyane, ukoresheje ingufu za 6KW hamwe na 220V icyiciro kimwe kibika ingufu nyinshi kugirango utange ibisubizo wifuza.

Birasabwa cyane uruganda ruto rwimitako cyangwa amahugurwa yimitako, gukora neza kandi igihe kirekire ukoresheje. Nubwo ari igikoresho gito, cyuzuza akazi gakomeye kubakoresha.

Igikoresho cyo kugenzura ubushyuhe nicyifuzo kuriyi mashini.

-

Automatic Zahabu Ifeza Bullion Vacuum Gutera Imashini 2KG

Kuki Uhitamo HasungicyuhoImashini yo guteramo zahabu?

Imashini ya Hasung Vacuum Ingot (HS-GV2) yagenewe guteramo ibiro 2 bya feza na zahabu nziza. Iyi mashini ya casting ije ihindagurika kubibumbano kugirango uhindure ibiceri bya feza na zahabu, ingots na bullions hamwe nubushushanyo bwawe nubunini.

Icyumba cya gaz ya inert yiyi mashini ya feza ya zahabu yerekana ko ufite casting ya nyuma ifite ubuziranenge buhebuje hamwe nindorerwamo ukuraho burundu ubwoko bwose bwimitsi, imivumba y'amazi cyangwa kugabanuka mubice byawe byanyuma.

Ugereranije nuburyo gakondo. Igikorwa cyawe cyose cyo gukina kizakorwa munsi ya vacuum na gaze ya inert. Gutyo, guha ibicuruzwa byawe bya casting ubuziranenge bwiza. Hamwe nimiterere yavuzwe haruguru abakoresha bawe bijejwe rwose gukoresha ibikoresho byacu byoroshye.

Ibice byumwimerere bya Hasung biva mubirangantego bizwi cyane murugo ndetse no kwisi yose nku Buyapani AirTec, Tayiwani Weinview, na Siemens yo mu Budage, Schneider, Omron, nibindi.

-

Automatic Gold Bullion Vacuum Gutera Imashini 12KG 15KG 30KG

Kuki Uhitamo HasungVacuumImashini yo guteramo zahabu?

Imashini ya Hasung Vacuum Bullion igereranya nandi masosiyete

1. Biratandukanye cyane. andi masosiyete vacuum igenzurwa nigihe. Ntabwo ari icyuho nyacyo. Bapompa gusa mu buryo bw'ikigereranyo. Iyo bahagaritse kuvoma, ntabwo ari icyuho, gusohoka vuba. Amapompe yacu gushiraho urwego rwa vacuum kandi arashobora gukomeza icyuho igihe kirekire.

2. Muyandi magambo, icyo bafite nigihe cyo gushyiraho icyuho.

Kurugero, kongeramo gaze ya inert nyuma yiminota umwe cyangwa amasegonda 30 byikora. Niba itageze mu cyuho, izahindurwa gaze ya inert. Nukuri Mubyukuri, gaze ya inert numwuka bigaburirwa icyarimwe. Ntabwo ari icyuho na gato. Icyuho ntigishobora kubikwa muminota 5. Hasung irashobora gukomeza icyuho mumasaha arenze makumyabiri.

3. Ntabwo turi bamwe. Twashushanyije icyuho. Niba uhagaritse pompe vacuum, irashobora gukomeza icyuho. Mugihe runaka, tuzagera kumurongo Nyuma yo gushyiraho agaciro, irashobora guhita ihindura intambwe ikurikira hanyuma ikongeramo gaze ya inert.

4. Hasung ibice byumwimerere nibirango bizwi cyane kuva mu Buyapani, Ubufaransa n'Ubudage.

-

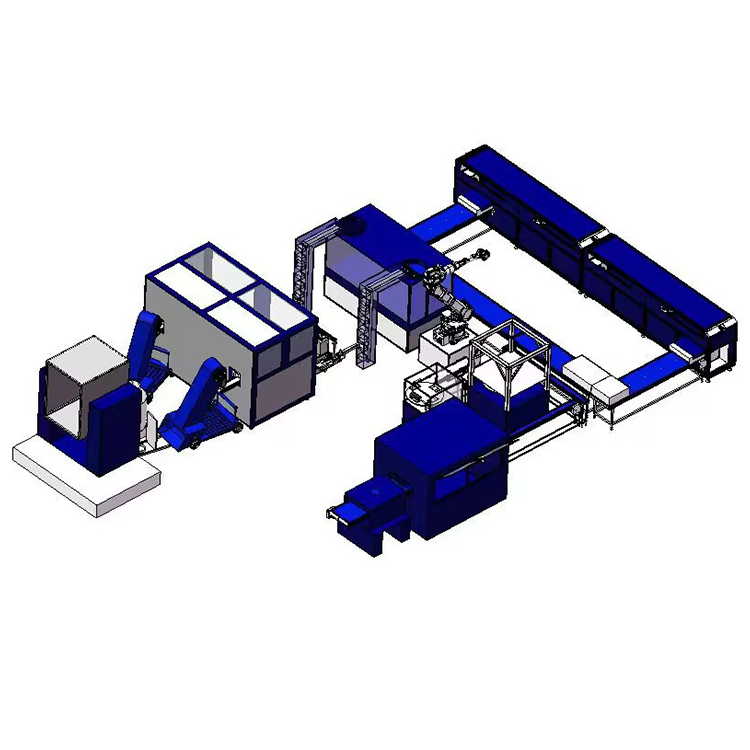

Umuyoboro Ubwoko bwa Zahabu Ingot Vacuum Sisitemu

HS-VF260 ni itanura ya tunnel ya induction, nubwo irimo ikoranabuhanga ryateye imbere cyane, iroroshye kandi yoroshye kuyikoresha. Biboneka muburyo butandukanye, buri Tera Automation HS-VF260 yarateguwe, icungwa kandi ikusanyirizwa hamwe muri sosiyete yacu.

Itanura ryacu rya tunnel rigabanyijemo ibyumba bitatu, aho ibinyampeke bishonga mu kirere cyagenzuwe hanyuma bikajugunywa mu ndabyo zuzuye kandi zuzuye zahabu cyangwa ifeza. Ikoranabuhanga ryemewe ryitwa Pinch Valves, rishyizwe kumpande zombi zumurongo, ritanga ikimenyetso gifatika: nkukuri, iyi sisitemu ifite valve pneumatike ituma ogisijeni hanze yumuyoboro, igakomeza umwuka mubi kandi igabanya gazi-cyane cyane azote - ikoreshwa . Imikoreshereze ya Graphite imara igihe kirekire kandi ntishobora kwangirika kubera okiside.

Kimwe nandi matanura yose ya induction, iri ziko rigomba guhuzwa nogushiraho amazi akwiye.

-

Imashini ya TVC Yinjiza Vacuum Umuvuduko wo Gutera Imashini ya Zahabu Ifeza

Imashini Yuzuye ya Vacuum Yumuvuduko

Ubuhanga bushya bwo kuzamura ibisubizo bya casting

Sisitemu ya Casting

1.Gufunga igifuniko mu buryo bwikora, byose birakora mu buryo bwikora kuri casting muri rusange biteza imbere ibintu no kuzuza ibicuruzwa

2.Ibicuruzwa byerekana ubucucike buri hejuru kandi buhoraho

3.Ubukene bwaragabanutse cyane

4. Ihangane na Max. Utubari 4 dutera igitutu.

5. Sisitemu yo guca SBS udakoresheje gasketi, uzigame ibiciro.

6.Castings ifite imihangayiko myinshi nuburyo bworoshye, bigatuma byoroha gutunganya neza.

7. Gukora byoroshye gukora hamwe nibintu byingirakamaro bya ecran

8. Gahunda 100 zirashoboka.

-

Imashini ya VPC Vacuum Umuvuduko wo Gutera Imashini

Umuvuduko hejuru yimashini zitera Vacuum

VCT ni umuryango wumuvuduko wimashini zitera vacuum zagenewe gukemura cyane ibikenerwa mu guta ibishashara byatakaye bya zahabu, K-zahabu, umuringa, umuringa, ibivanze. Bakunze gukoreshwa muguhuza 3d printer ya casting itaziguye kugirango babone ibyuma byambere byibintu bigoye.

Uyu muryango wimashini ukorana nigitekerezo gishya, cyimpinduramatwara ibyumba bibiri. Sisitemu yo guhanga udushya itanga ibyiza byinshi ugereranije na gakondo imwe ya chambre sisitemu yo kuboneka ubu ku isoko.

Muri VCT, icyumba cyo gushonga hamwe nicyumba cya flask birigenga rwose: mugihe cyo gutera, imashini irashobora kugenzura inshinge zicyuma mubibumbano ukoresheje igitutu gitandukanye mugihe cyo gusuka. Ibi bitanga inshinge yihuse ugereranije nuburemere bworoshye busuka hamwe ninyungu zo guta ibintu mubushyuhe buke. Ibi bizavamo neza neza kurangiza no kugabanya kugabanuka kwibice.Umukino wo gukina utwara iminota mike gusa, kandi mugihe flask yabanje gukonjesha muri gaze ikingira kugirango hatabaho okiside, amafaranga akurikira arashobora kwinjizwa mumashanyarazi kandi akayashonga, bityo akazenguruka inshuro ebyiri kugirango atakaza umwanya.

Imashini irikora rwose, igaragaramo sisitemu ya PC yo kugenzura ibipimo byo kugura no gucunga amakuru yumusaruro, hamwe no guhindura byoroshye gahunda ya casting ikwiranye nubwoko bwinshi.

Iyi mashini yimpinduramatwara ni synthesis yubuhanga bugezweho kandi nuburambe mu myaka yo gukina Hasung gusa azazana uruganda rwawe.